The last time I posted a Tiny Whoop DIY build guide was eight years ago! Since then, the FPV world has seen impressive advancements, and now you don’t necessarily need to build your own Tiny Whoop. Bind and Fly (BNF) models perform brilliantly out of the box and are often cheaper than building your own. However, building a Tiny Whoop from scratch is still a fantastic way to learn the basics of FPV drones, understand how each component connects, and it can be a fun project. In this tutorial, I’ll guide you through an affordable, extremely high performance Tiny Whoop build. We’ll go over the essential components, assembly process, and some useful tips to make your first build a success.

Why Build a Tiny Whoop?

If you’re interested in learning how to build a Tiny Whoop and dive into the world of FPV drones, Tiny Whoops are an excellent starting point. Building a lightweight Tiny Whoop is fun, rewarding, and a lot less intimidating for beginners—especially if you’re new to FPV drone flying.

These micro drones are affordable, compact, and lightweight, making them much safer to fly than larger drones like a 5-inch quad. Since they’re designed to withstand crashes without causing damage, they’re ideal for new pilots who want to practice flying without fear.

This build minimizes soldering, keeping it simple for beginners. For this Tiny Whoop, you’ll only need to solder the motors to the flight controller—just three pads per motor. The rest is plug-and-play, making it a perfect project if you’re new to soldering or want to keep things straightforward.

Parts

The goal for this Tiny Whoop build is to keep the total weight under 17 grams, resulting in a powerful and nimble micro drone. Achieving this is no easy feat—the lightest Tiny Whoop on the market is just over 17g, so staying under this weight requires careful planning and precise execution.

For comparison, the Mobula6 2024 (right) weighs 17.7g, the Air65 (middle) weighs 17.2g, and my custom build (left) only weighs 16.8g.

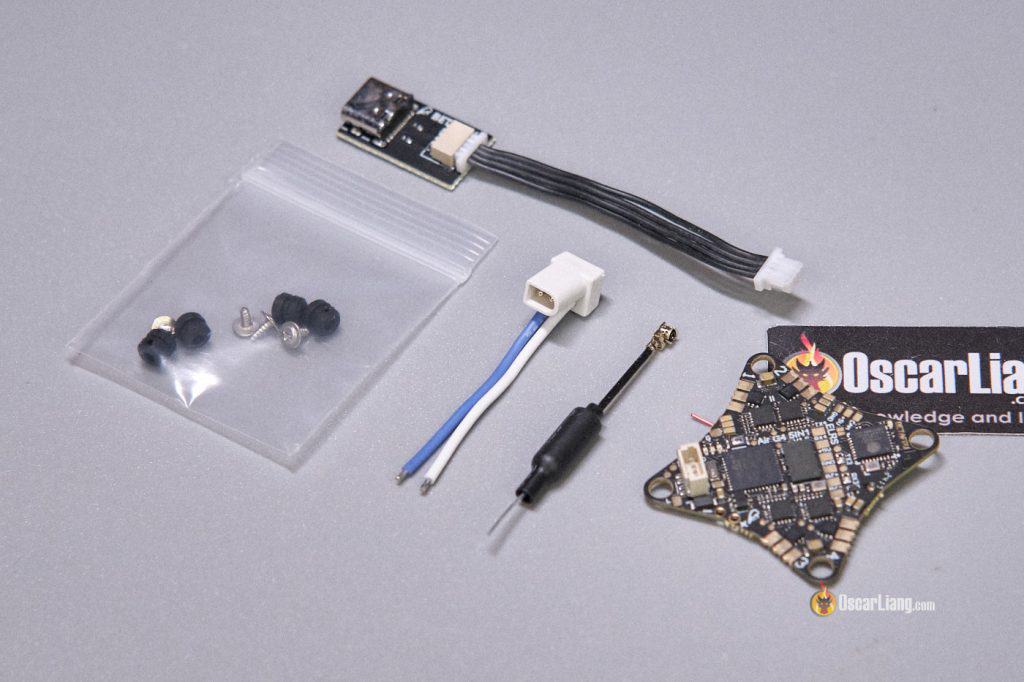

The components selected are cutting-edge, offering performance that you won’t find in an off-the-shelf whoop. Here’s what you’ll need to build a Tiny Whoop for around $130:

- FC / VTX / RX / 4in1 ESC: BetaFPV Air 5-in-1 AIO FC ($50)

- Motors: 4x BetaFPV 0702 30000KV ($49)

- FPV camera: BetaFPV CO3 camera ($20)

- Frame: NewBeeDrone Cockroach LiteAF ($5)

- Canopy: BetaFPV Micro Air Canopy ($3)

- Propellers: HQ Ultralight Triblade ($2.5)

Building your own tiny whoop will be more expensive than a pre-built model, and you’ll need to assemble it yourself. If you’re looking for a ready-to-fly experience, the BNF model is a great choice. But if you’re after the satisfaction of building your own drone with top-notch performance, this guide is perfect for you.

BetaFPV Air 5in1 AIO Board

The star of this build is the BetaFPV Air 5in1 AIO board, which is an absolute game-changer. Weighing only 4.9g, this board integrates the flight controller, ESC, OSD, VTX, and ExpressLRS receiver into one lightweight unit. This setup not only simplifies the build but also reduces weight significantly. A 4in1 version without a receiver is also available, but I recommend the 5in1 version unless you plan to use a different receiver like the TBS Crossfire Nano.

Get it here:

BetaFPV 0702 30000KV

For this build, I chose BetaFPV’s latest 0702 30,000KV motors. These high-KV motors shine in ultra-light builds, offering unimaginable responsiveness and speed. Lower-KV versions, like 27000KV or 23000KV, can offer better flight time, but in ultra-light builds, they tend to feel less powerful – this was particularly noticeable when I was testing them back to back. The higher-KV motors also offer more flexibility, as you can adjust motor output or scale down throttle in Betaflight if you prefer a slower, more controlled flight experience. I have a tutorial explaining how to scale down throttle here: https://oscarliang.com/reduce-power-throttle-taranis-betaflight/.

Get it here:

NewBeeDrone Cockroach LiteAF Frame

The NewBeeDrone LiteAF frame, weighing only 2.4g, is currently the lightest frame on the market.

Get it here:

The BetaFPV Meteor65 Air frame is a great alternative, used in the Air65 model, and weighs slightly more at 2.8g with slightly higher durability. Get it from BetaFPV: https://oscarliang.com/product-d2cs

BetaFPV Air Canopy

I chose the BetaFPV Air Canopy for its compatibility with the camera we are going to use. It’s simple, effective, and lightweight, matching well with the rest of the components in this build.

Get it here:

BetaFPV CO3

For video, I opted for the BetaFPV CO3 analog camera, which provides a great balance between image detail and field of view. It comes with a connector, which you can plug straight into the BetaFPV AIO board without any soldering, making assembly straightforward.

Get it here:

HQ Ultralight Triblade

These HQ Ultralight Triblade props are ideal for high-KV 0702 motors (like the 30000KV we are using) due to their lightweight design (about 0.5g per 4 props). They require less torque to spin, providing a great balance between performance and durability. Another popular option is the Gemfan 1219S (about 0.8g per 4 props), which is slightly more durable but a bit heavier. Both are excellent choices for a 65mm Tiny Whoop build.

Get it here:

Other Components

To fly this Tiny Whoop, you’ll need a few additional parts and pieces of equipment.

Here are my recommendations:

For more Tiny Whoop-related accessories, check out this post: https://oscarliang.com/best-tiny-whoop/

The Build Process

Preparing the FC

Solder the BT2.0 battery lead to the power pads on the flight controller (FC), paying careful attention to polarity—the blue wire is + (positive), and the white wire is – (negative).

Preparing the Motors

If your motors come with connectors, you’ll need to cut them off, leaving about 28-29mm of wire from the motor base. Dry-fit the motor and FC to double-check the necessary wire length.

Be mindful not to cut off too much wire, as this could put excess stress on the solder joints later on. Ideally, leave a bit of slack. If there’s too much slack, you can twist the wires to prevent them from dangling or interfering with the spinning propellers.

Some whoop FC comes with motor connectors, you can just plug the motors in without soldering. However these add weight and introduce more electrical resistance than direct soldering. For maximum performance, direct soldering is preferred.

Strip a bit of insulation from the ends of the wires and tin them with fresh solder.

Soldering the Motors

Tin the motor pads on the flight controller and apply a small amount of solder flux to these pads, ready to be soldered.

Solder the motor wires to the motor pads on the board. These pads are small, so a steady hand and patience are needed, especially if you’re new to soldering. Work quickly to avoid overheating the pads, as this could cause them to lift and permanently damaged.

The specific order of the wires doesn’t matter, as you can adjust motor rotation direction later in software.

New to soldering? Check out this basic guide: https://oscarliang.com/soldering-guide/

Mounting the FC

Insert the rubber grommets in the four corner holes of the FC.

Drop the FC into the frame, ensuring the correct orientation—usually indicated by an arrow pointing forward, with the battery connection at the back.

Mounting the Motors

Install the motors on the frame with the provided screws. They come with two types, metal and plastic screws. I chose to use the plastic ones as they are lighter. However they are a bit bit too long, you could trim them to about 1.5mm thread length using a nail clipper.

If the motor wires have slack, twist them slightly before installation to keep them tidy and avoid stress on the solder joints.

Installing the Camera and Antenna

Install the FPV camera and VTX antenna in the canopy.

Plug the camera into the FC.

Installing the Canopy

I noticed that the canopy interfered with the UFL antenna connector, and this has been a known issue in the Air65 as some users report that crashes can cause the connector to pop off.

To avoid this, trim the canopy slightly to allow space for the connector. Consider adding a dab of E6000 glue too to the UFL connector to help secure it during crashes.

Mounting the Propellers

Put the props on, depending on whether you want to run “props in” or “props out”. In my example I am running “props out”.

And that’s it—your Tiny Whoop assembly is complete!

Betaflight Configuration

Once your Tiny Whoop is assembled, it’s time to configure it in Betaflight. New to Betaflight? Check out my beginner’s guide: https://oscarliang.com/betaflight-firmware-setup/

Connect the USB adapter to the flight controller (FC) and plug the USB cable into your computer.

Here are some tips on optimzing your tiny whoop configurations: https://oscarliang.com/best-tinywhoop-settings/

Below are screenshots of my Betaflight Configurator settings for this build. If you’re using the same setup, you can easily replicate my configuration by copying and pasting my CLI file here.

ESC Configuration

The BetaFPV AIO FC comes preloaded with Bluejay 0.19 firmware at 96KHz. I recommend flashing the latest version—Bluejay 0.21 at 48KHz—for optimized performance. You can learn how to flash Bluejay firmware here: https://oscarliang.com/bluejay-blheli-s/

Flight Performance

I successfully achieved my target of a sub-17g build, and the first flight exceeded my expectations.

With a 1S 300mAh battery, I achieved a flight time of around 3:15 minutes when flying aggressively—about 10-15 seconds less than with the 27000KV motors. However, the boost in flight performance is well worth it, in my opinion. It’s similar to moving up from 23000KV to 27000KV; the build felt significantly more powerful, agile, and nimble, almost like flying a whoop with much less weight.

Final Thoughts

This is how you can build a Tiny Whoop with exceptional flight performance for just $130.

This build offers one of the easiest ways to start assembling FPV drones from scratch and gain a solid understanding of them. It’s affordable, safe, and provides a hands-on introduction to assembling, configuring, and flying an FPV drone. You’ll also develop basic soldering skills with minimal risk, as only the motors require soldering.

Whether you’re practicing indoors or flying in tight spaces, this Tinywhoop offers a fun and educational experience that can build your confidence before moving on to larger drones.