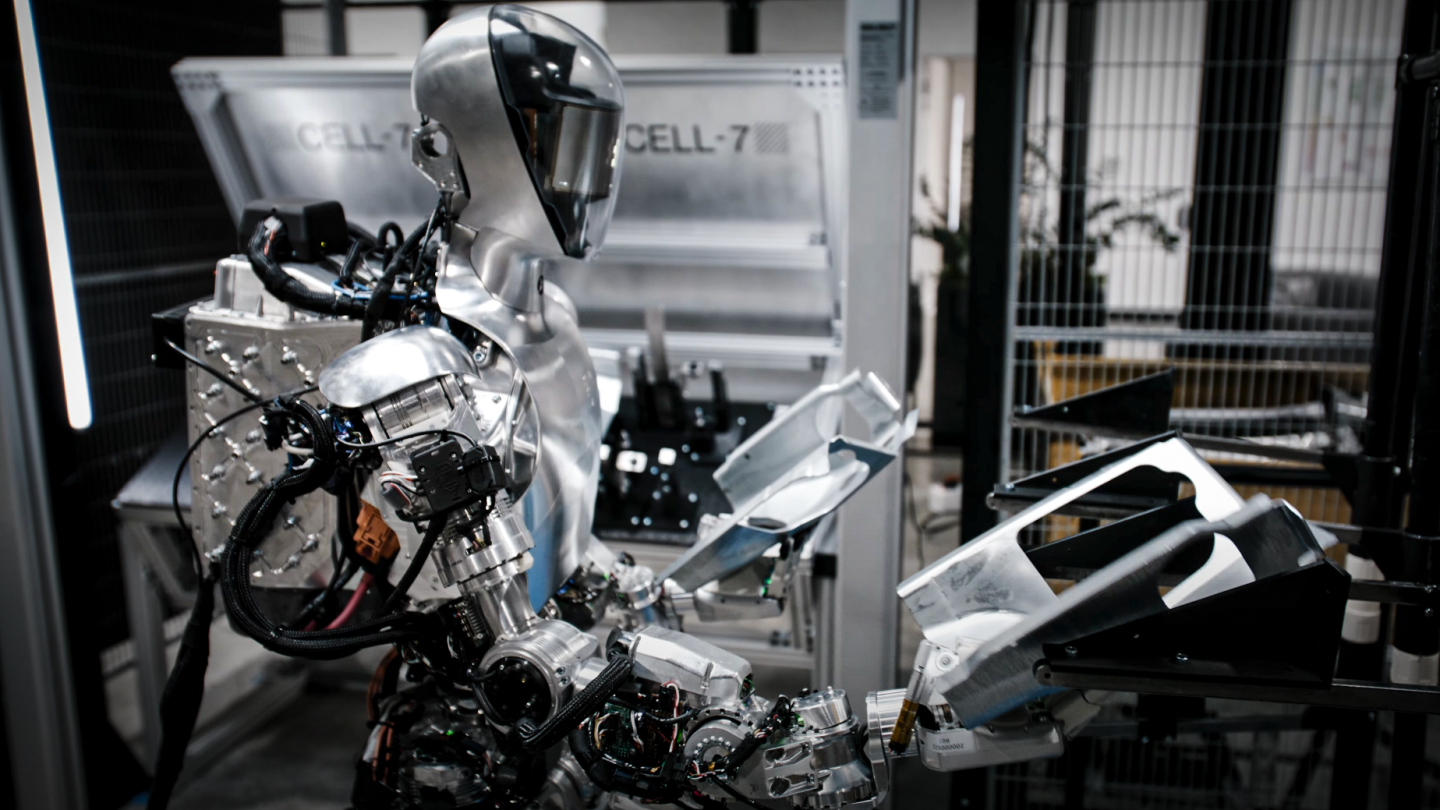

Nearly six months ago, Figure announced that a shiny silver humanoid robot had landed its first job at a BMW manufacturing plant. The robot was trained for the occasion, and a new video shows just how far the versatile worker has come.

The AI-based humanoid robots currently in development are vastly different in terms of hardware and learning methods, but they all focus on the same goal: to perform any physical task that a human can do, and to do it more cheaply and consistently.

As they learn more about what they do, these companies can sell more robots, potentially decoupling economic growth from population figures and unlocking a source of labor that is limited only by resources. It sounds like a pipe dream, but the hardware looks surprisingly capable, and the AI models that train and control these robots, while certainly still in their infancy stages of development, seem to be advancing at an impressive rate.

When these machines start talking, using OpenAI’s speech engine and language models, you really get a sense of how different they are from traditional industrial robots.

Image Status Update – OpenAI Speech-to-Speech Inference

True general-purpose humanoids are still a long way off, but the companies building them want to get them up and running as quickly as possible, performing simple, useful tasks in real-world customer operations. It’s likely that collecting data and educating customers on how to work with the next generation of AI employees will be more important than generating real revenue. But either way, auto manufacturing appears to be a key industry for early adoption of humanoid robots.

For example, Apptronik has contracted with Mercedes to test its Apollo bots. Even the venerable Boston Dynamics Atlas robot has been seen training for car manufacturing jobs.

Sure, Tesla has its own massive car manufacturing facility where it can train, test, and get early value for its Optimus bots. But Figure founder Brett Adcock thinks this in-house approach is too generous for Tesla’s robots, tweeting, “Having an external customer to fire us if we fail would be a competitive advantage for Figure.”

Today we will take a look at how the Figure bot is trained in the fully autonomous driving ‘BMW Full Use Case’ video below.

Picture Status Update – BMW Full Use Cases

This isn’t the most earth-shattering video we’ve ever seen of a humanoid robot, but there’s a lot to like about it. 01 is learning to grasp large, complex shapes with its rubber-tipped fingers. It’s learning to move things without bumping into them. It’s not a skill I’d recommend to my kids just yet.

It is no easy task to get a large plate onto that jig, even when the two positioning pegs needed to pass through the holes are blocked by the plate.

Picking up two small pieces with one hand isn’t that impressive, since it’s a human doing two at a time. But it correctly identifies that they are misaligned, orients and aligns them to the jig, and makes them pop out the right way. And when it notices that they are misaligned, it corrects its own error by tapping them in place with the back of its hand.

On the other hand… well, as one cheeky YouTube commenter pointed out, they’re clearly paying by the hour, not by the day. But to Figure’s credit, the company is clearly not speeding up the video, and this kind of behavior will only get faster and smoother over time.

Picture Status Updates – Real World Work

This may not seem like a huge step forward from the company’s first real-world task demo from February, shown above. Both could be categorized as “pick up and put down” type tasks, so this update feels more evolutionary than revolutionary.

But 01 is definitely a much more complex and interesting shape, and requires a more complex grip. And it’s not just about placing boxes on a conveyor belt, it’s about aligning complex parts to fit them into a precision jig.

The video ends with “BMW Group, Spartanburg Plant,” but it appears to have been shot on test equipment at Figure’s own building. Assuming that’s the case, it’s unclear when the 01 might be in operation at a BMW production site.

shame

It will be interesting to see how these robots perform in real-world tasks. They will likely be slow, cumbersome, and limited at first, but as AI behavioral models improve, both their movements and the speed at which they learn skills will increase.

But to take over the world, to be produced in the millions, and to cause massive changes across society, you need to demonstrate a clear economic advantage over today’s meat-and-bone workers. That’s where things start to get really interesting!

Source: Picture