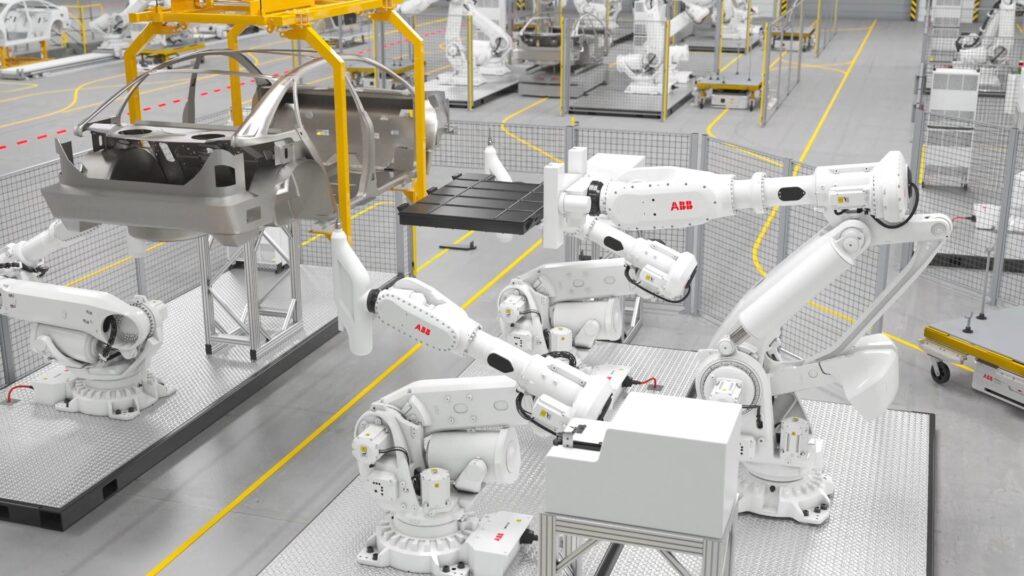

With the launch of the new IRB 7710 and IRB 7720 models, ABB Robotics continues to expand its large portfolio of modular robots. With the recently launched models IRB 5710-IRB 5720 and IRB 6710-IRB 6740, the range now includes a total of 46 variants with load capacities from 70 kg to 620 kg, offering customers the highest level of flexibility, choice and performance.

“Companies are increasingly relying on new technologies and components to achieve their productivity and sustainability goals. “We have therefore designed a range of large-scale modular robots to enable our customers to choose the most suitable robot and variant for efficient tasks,” explains Marc Segura, head of ABB Robotics. “We have the most comprehensive portfolio of mechatronics platforms on the market, including industrial robots, cobots and AMRs. The new robots expand these offerings and help our customers respond to labor shortages and be competitive while being sustainable.”

The new ABB robots IRB 7710 and IRB 7720 are available in 16 variants and support applications in a variety of industries. Manufacturers of electric, hybrid and combustion vehicles can choose from the wide range of ABB robots the ideal variant for different applications – from press automation to body production, battery production and final assembly. These robots are suitable for high-volume assembly tasks such as gigacasting, high-speed press loading and palletizing, as well as high-precision contact applications such as machining and friction stir welding.

ABB OmniCore™ controllers ensure the highest level of motion control of robots with a path accuracy of 0.6 mm. This also applies when multiple robots move loads of up to 620 kg at speeds of up to 1,600 mm/s. Additionally, customers benefit from up to 25% reduction in cycle times while improving productivity and quality. The automotive industry can use the IRB 7710 with the latest OmniCore control to increase production on a robot-assisted press line from 12 to 15 strokes per minute, producing 900 parts per hour. In the construction sector, new robots can support the growth of modular construction, for example, used in steel frame production and surface finishing operations, helping to increase speed and quality.

The IRB 7710’s energy-efficient design, combined with OmniCore Control’s regenerative technology, can reduce energy requirements by up to 30% while supplying energy back to the grid through an integrated power pack.